D.I.D Ultimate Power Chain Series

D.I.D Ultimate Life Chain Series

D.I.D Environment Resistant Chain

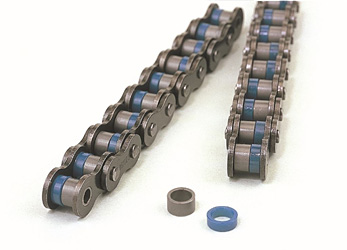

The D.I.D O-ring Chain demonstrates significantly enhanced durability, as the grease is sealed between the pins and bushings by O-rings. The O-ring chain is recommended for use in environments characterized by abrasive conditions that necessitate regular maintenance, or in scenarios where sintered bushing roller chains are unsuitable due to their limited ability to handle shock loads or high-speed operations.

The D.I.D UR Roller Chain features bushings constructed from a sintered alloy infused with lubricating oil during manufacturing. This sintered bushing roller chain is designed to be maintenance-free, making it ideal for applications where lubrication is not permitted. The rust-resistant variant (URN) is an excellent choice for environments where appearance is a priority. Additionally, in certain applications, it is recommended to limit the operating speed to 492 ft/min or less. In settings characterized by dust, the use of an O-ring chain is suggested.

The URF variant of the D.I.D UR Roller Chain is engineered for heat resistance, capable of functioning effectively at temperatures up to 400°F. At this temperature, the wear life of the URF chain is two times that of the standard UR chain.

The D.I.D Stainless Steel Chain is offered in two variants: the SS chain, which consists entirely of austenitic steel components (SUS304, 18-8 stainless steel), and the SSK chain, featuring pins, bushings, and rollers constructed from quench-hardened stainless steel (SUS631), while the plates are made of austenitic stainless steel (SUS304). The SS chain is recognized for its superior corrosion and heat resistance, making it suitable for applications in chemical plants, food processing machinery, water treatment facilities, and similar environments. However, it is important to note that due to its austenitic composition, the tensile strength of the SS chain is only about 70 percent that of a standard roller chain, with a maximum allowable tension reaching merely 10 percent of that standard. These characteristics should be thoroughly assessed when considering the SS chain for your needs.

In contrast, the SSK chain offers enhanced performance, boasting a maximum allowable load that is 1.5 times greater than that of the SS chain. This is achieved through the increased strength of its pins, bushings, and rollers. Both the SS and SSK chains maintain comparable levels of corrosion resistance.

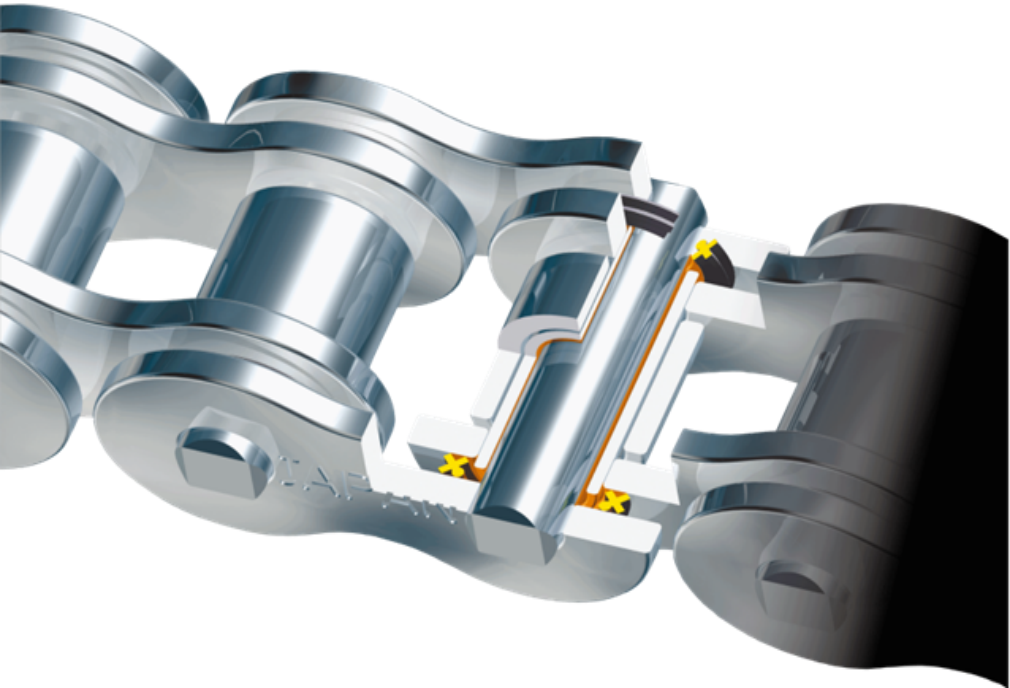

There is an increasing demand for reduced equipment noise in critical work environments. To address this need, the D.I.D Low Noise Chain Series has been significantly improved to offer enhanced sound-dampening capabilities. This low-noise chain is particularly beneficial in sectors such as printing, packaging, engineering, parking, and various conveyor systems.

The chain’s innovative “two-piece roller structure” contributes to substantial noise reduction. When the chain engages with a sprocket, the unique elastic deformation of the specially designed elastomer rollers helps reduce audible shocks, achieving noise reductions of up to 10 DB. Furthermore, when utilized in conveying applications, the chain significantly reduces the sliding noise generated between the rails and the rollers. The D.I.D Low Noise Chain Series is available in sizes ranging from RC40SLN to 80SLN.